ADVANTIQX IMPLANT

So you have more time for the patient, less administrative work and lower costs.

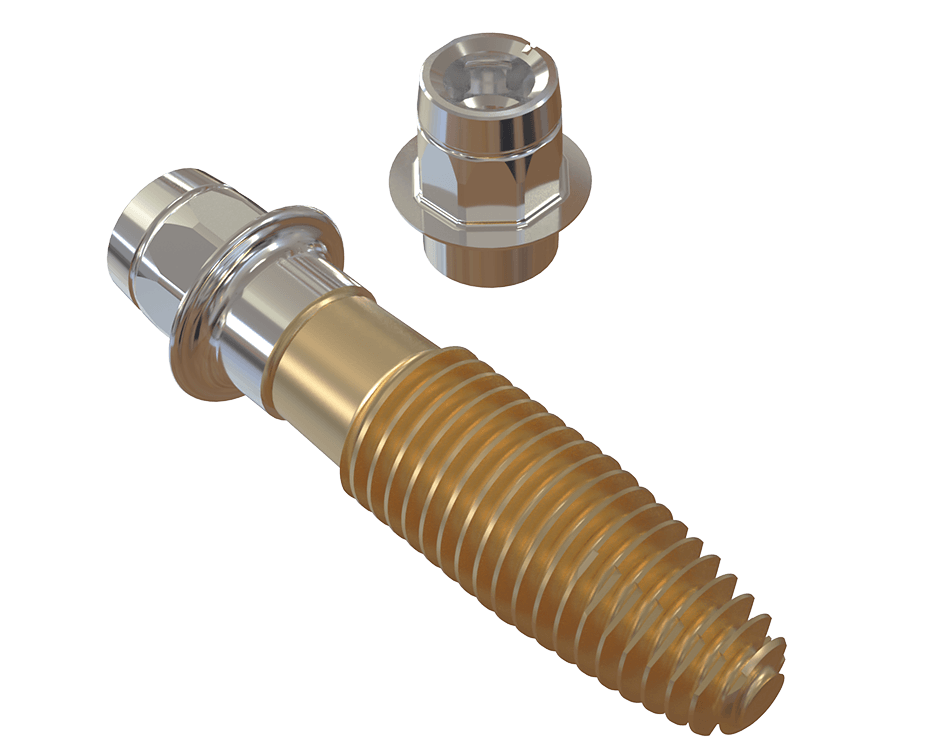

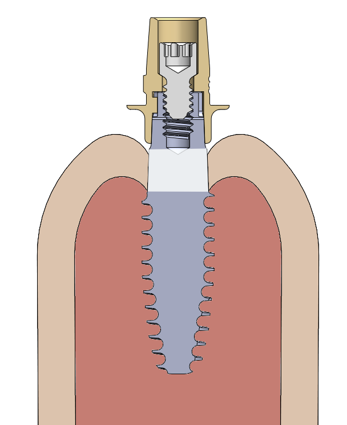

External cone

At the critical point in the crestal area, our implant is thinner and at the same time more massive. This is only possible through the external cone.

Our titanium implant is ceramicised in the crestal area for optimal ingrowth behaviour without being brittle.

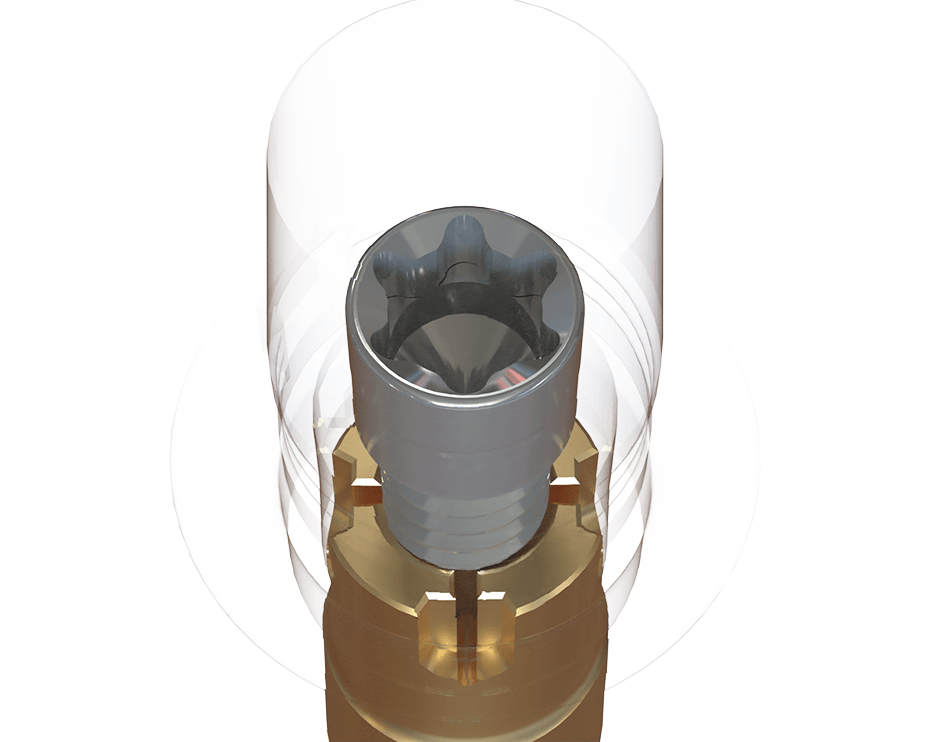

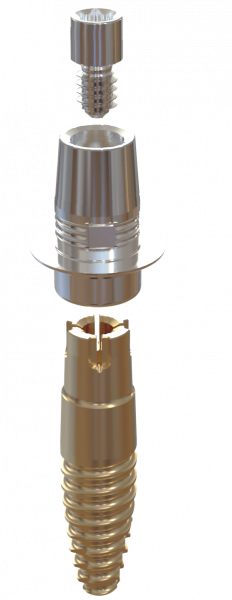

Implant abutment connection

Unique connection: The fixing screw tightens the abutment and implant to form a single unit after the clinician’s try-in.

The three parts form a one-piece implant for the patient for a secure hold.

Multifunctional cap

The multifunctional cap is pre-mounted on all straight implants. It is used for screwing in the implant, scanning the position of the implant and temporary restoration of the patient.

Lean system. Less than 200 parts.

Less is more: The complete system consists of less than 200 parts.

This means that the practitioner and the team always have an overview of all parts.

3 abutments for all applications:

Multi-Unit, CAD/CAM abutment or abutment with patient-specific milled crown. For maximum individuality without a lot of frills.

1 implant abutment connection:

All implant variants have the same connection and all abutments can be placed. This reduces the planning effort and simplifies the system.

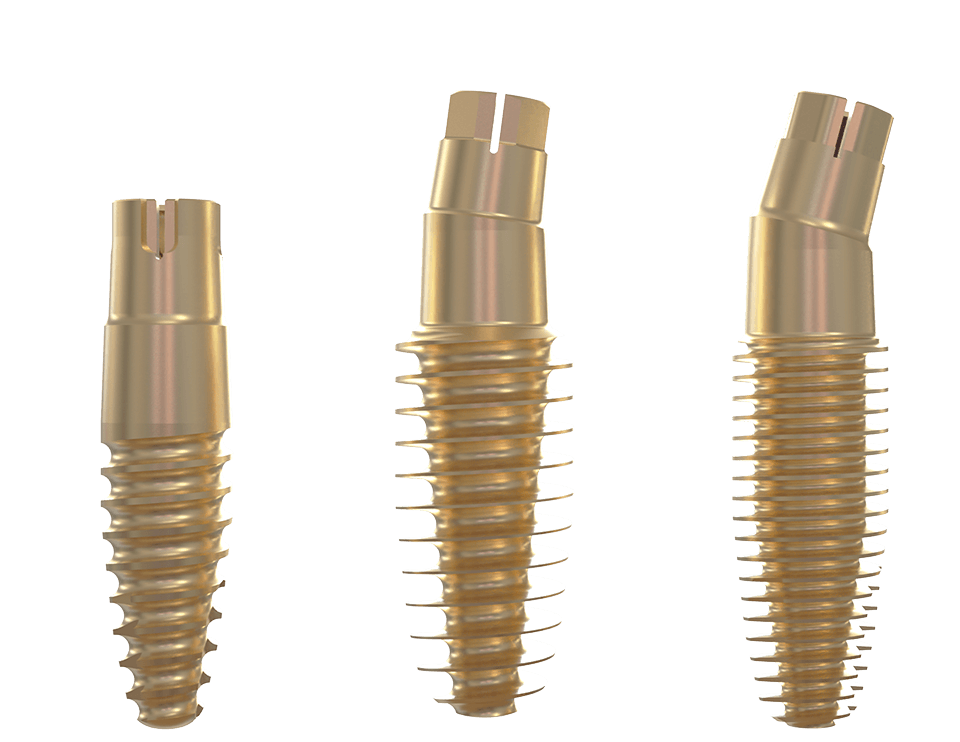

Versatile with 35 implant variants:

With our system all indications can be covered with one system. The connection always remains the same and the restoration is simple. Many implant variants have been submitted for patent.

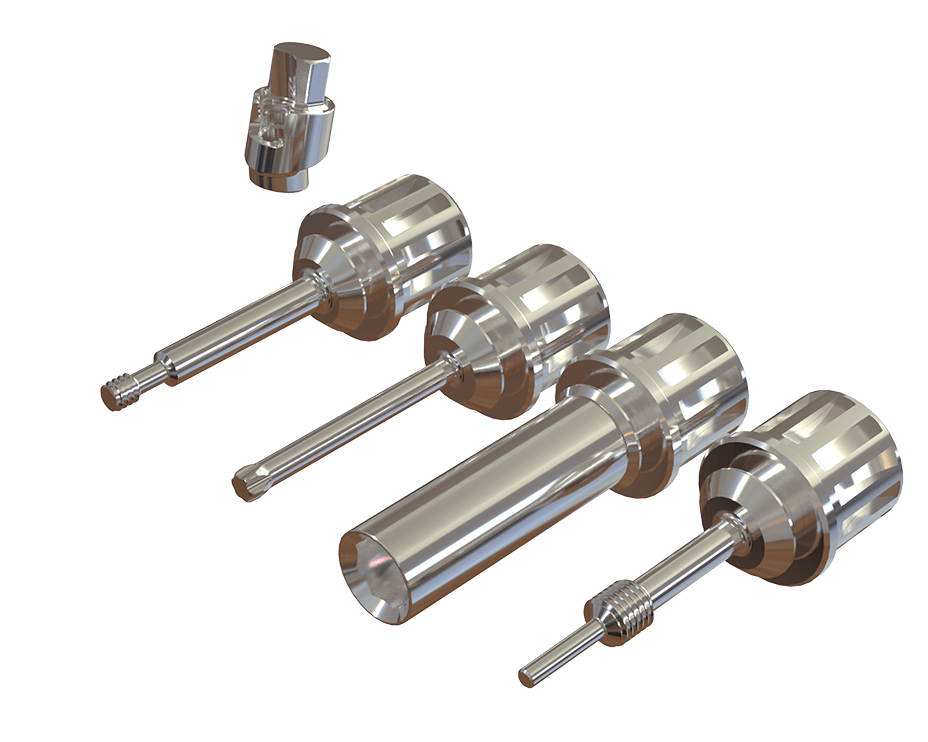

Less than 100 accessories

Of the 200 parts of the overall system, there will be less than 100 accessories while having a full or greater functional scope. Many parts have more than one function without being too complex.

That means for you:

Less administrative effort. Less costs. More time for the patient.

Fully digital because of angled implants

Angled implants allow implant abutment connections to be aligned after prosthetics and ensure predictable results.

Even in unfavorable situations a restoration without visible screw connection is possible.

This makes the implant fully digital and more esthetic for the patient.

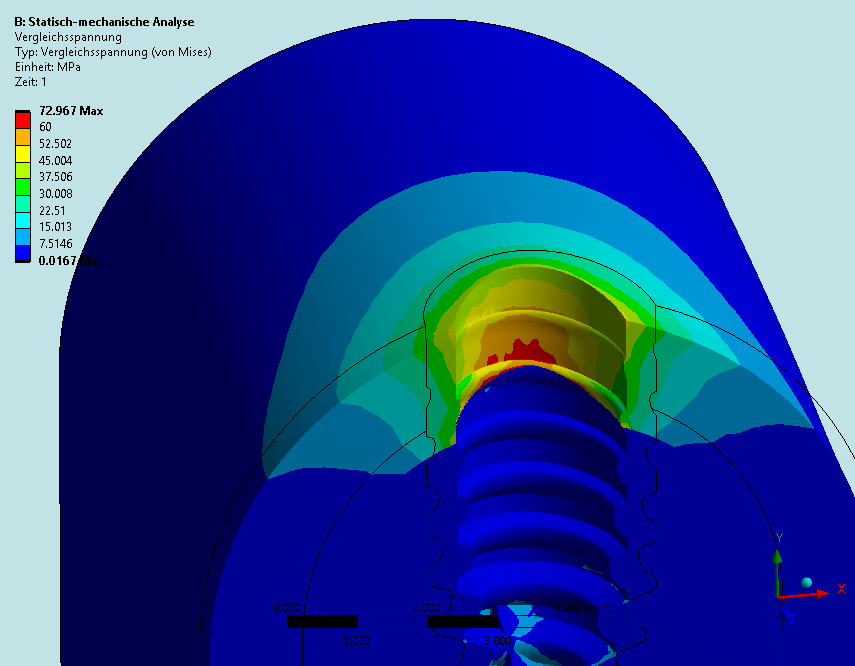

Optimized load on the crestal bone

By means of finite element simulations on the high-performance computer, we achieve the optimal power transmission between implant and bone: in both crestal and cancellous bone.

This avoids both overloading and underloading, thus preserving the bone and protecting the implant.

Tissue-Bone-Level

Zeit, etwas zu verändern.

Wir dürfen bei Implantaten keine Kompromisse eingehen. Aus diesem Grund machen wir Implantate einfach und sicher. Für Patienten, sowie für Ärzte.

Melden Sie sich hier zum Newsletter an und erfahren Sie als Erster von wichtigen Neuigkeiten: